Latest News

RAM3D – The shaping of things to come

12 July 2025

In an evolving manufacturing world, our stainless steel industry has to stay agile and relevant – a key part of this is 3D metal printing and RAM3D is a leading player in the field

Traditionally speaking – subtractive manufacturing

In conventional machining, pieces of material are removed from an oversized stock of material to shape the required component – this is subtractive manufacturing. And components are also produced through casting, where molten material is poured into a mould, using various means.

Looking to the future – additive manufacturing

However 3D printing – or additive manufacturing – works the opposite way. The component is built up layer by layer, as is commonly seen with basic plastic 3D printers.

Due to the high melting temperatures required, metal 3D printer manufactures came up with several ways to engineer printers to overcome their shortcomings. One of the most efficient, and the one we are looking at here is called Direct Metal Laser Melting (DMLM). The working material used in a DMLM printer is fine metal powder – in this case a fine stainless steel powder. A thin layer of the powdered metal is spread over the entire area of the print chamber.

Instructed by a specific CAD file format a laser is used to selectively melt the shape which is part of the design. In that moment, one layer of the part is made. The 3D printer then spreads another layer of powder and again the laser touches the correct spots for each layer to essentially meld the 3D object together. This process continues until the 3D project is created and at the end of the print process the loose powered metal surrounding the part is brushed away ready for use on another part. Once the part is removed from the printer it has any support structures removed and can then be treated the same as a part made via machining etc.

This is a broad overview of what is a specialised process but make no mistake the advantages of this now well established manufacturing technology are strong and many.

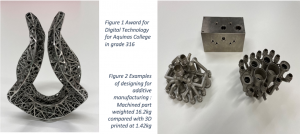

Complex shapes

A leading advantage of metal 3D printing is the ability to produce parts and objects with complex shapes. The technology unlocks a wealth of manufacturing opportunities by achieving what would be impossibly complex forms for conventional manufacturing.

Precision outcome

This process creates extremely precise forms – thereby being suitable for all manner of stainless steel forms, and the parts have the same or better mechanical properties as parts that are machined.

Saving on materials (green thinking)

Unlike traditional manufacturing methods, 3D metal printing uses only the material needed to produce the part – and the powder residue left over is emminently recyclable.

Keeping costs down

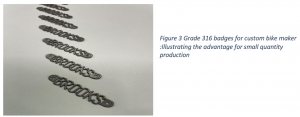

For some parts the costs can be very competitive, especially those which are challenging to machine. The process also has effectively no tooling so there are very few limits on production numbers and little impact on the cost.

Compact process (green thinking)

Compared to conventional production processes, machines, and raw materials, metal 3D printing requires less floorspace and very little energy. Plus products can be printed when needed – eliminating the space required to store excess products.

Flexible, flexible, flexible

3D printing is flexible as a given 3D printer can produce any design that will fit within its build volume. This leaves traditional manufacturing – where new tools, die, jig, etc. may be needed to create each new part – in the dust.

Faithful to stainless steel’s material advantages

So how does a process like this hang on to all stainless steel’s great material advantages? How can it have a beautiful finish and be impervious to rust, as two examples? Essentially, the stainless steel powder is just that, our favourite alloy with all its attributes in tact, before and after the 3D printing process.

Enter RAM3D – a leader in a growing, exciting field

RAM3D is the largest 3D metal printing service provider in Australasia, with a focus on Direct Metal Laser Melting.

Diverse manufacturing applications

The company’s state of the art additive manufacturing hub based in Tauranga, New Zealand, serves a range of sectors including aerospace, defence, aviation, marine, bike/cycling and food manufacturing – everything from drone parts to custom handlebar extensions. Essentially, RAM3D prints stainless steel parts — along with other metals and alloys — for a diversity of global industries.

Experience counts

While the industry is comparatively young, RAM3D has been metal 3D printing parts for more than 10 years. With that wealth of experience comes the knowhow to help you with your design, assess its viability, and if need be point you to a design professional to realise the desired part.

Quality control

Quality control is also next level with an in-house system which collects data on each build to ensure traceability.

In summation – 3D Metal printing has a shining future

- Offering dextrous manufacturing that can shape pretty much anything

- Economical processes – in terms of minimal waste and factory space, together with less staffand plant required

- Eminently green attributes so vital in today’s accountable market place

- Agile – print five, print a hundred – and first of all just print one for complete peace of mind